Thingybotting in Mooselake

2 posters

Page 1 of 1

Thingybotting in Mooselake

Thingybotting in Mooselake

UPS shows two packages in the local depot for delivery tomorrow. The Thingybot is 30 pounds, and a 6 pound package for the filament.

UPS gets here mid to late afternoon (hard to get early delivery in the swamp), and I'll be at work/woodshop all day Tuesday, so the unpacking and setup pics might not make it until Wednesday.

Kirk

UPS gets here mid to late afternoon (hard to get early delivery in the swamp), and I'll be at work/woodshop all day Tuesday, so the unpacking and setup pics might not make it until Wednesday.

Kirk

Last edited by Mooselake on Fri Dec 02, 2016 2:02 pm; edited 1 time in total (Reason for editing : Change Topic Title)

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

And it's arrived! Unboxing pictures taken but need a little cropping, the only problem is not being able to find the description of which way the 12 pin connector goes - with heatshrink over it it's pretty featureless. Needs a sticker or other way to tell which side is which, particularly when the description says it'll destroy the printer if connected wrong. Otherwise looks good, did a preliminary power on check (without the effector connected), lighte up and text appears on the display.

I've never had a printer with an LCD before, while it displays the pushbutton and rotary switch didn't seem to do anything. Might be related to no effector connection Next up is to see what Repetier-Host thinks of it while waiting for the connector directions.

I've never had a printer with an LCD before, while it displays the pushbutton and rotary switch didn't seem to do anything. Might be related to no effector connection Next up is to see what Repetier-Host thinks of it while waiting for the connector directions.

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Installed the probe and tried to calibrate, at bedtime it was reporting "TowerC Radius Error" and continuing. When I got up it was still calibrating. I killed it, figured it wasn't going to finish and didn't want to leave it running while I was at work. Same messages:

04:03:31.559 : TowerC Radius error - adjusting

04:03:31.563 : Adjusting Delta Radius (134.04 -> 134.04)

04:03:31.563 : Adjusting Diag Rod Length (276.51 -> 276.51)

04:03:58.525 : Z-Tower Endstop Offsets

04:03:58.529 : -7.8000 -7.6000 Tower Position Adjust

04:03:58.533 : -8.5625 -8.5500 I:-3.20 J:1.61 K:-53.82

04:03:58.533 : -7.6125 Delta Radius: 134.0357

04:03:58.537 : X-Tower Y-Tower Diag Rod: 276.5052

04:03:58.537 : Adjusting Delta Radius (134.04 -> 134.04)

04:03:58.541 : Adjusting Diag Rod Length (276.51 -> 276.51)

04:04:24.315 : Z-Tower Endstop Offsets

04:04:24.320 : -7.7250 -7.6375 Tower Position Adjust

04:04:24.324 : -8.5500 -8.6000 I:-3.20 J:1.61 K:-53.85

04:04:24.328 : -7.6500 Delta Radius: 134.0360

04:04:24.719 : X-Tower Y-Tower Diag Rod: 276.5052

04:04:24.720 : Adjusting Delta Radius (134.04 -> 134.04)

04:04:24.720 : Adjusting Diag Rod Length (276.51 -> 276.51)

07:06:18.174 : Z-Tower Endstop Offsets

07:06:18.178 : -9.0500 -8.9875 Tower Position Adjust

07:06:18.182 : -10.4000 -10.3750 I:-3.20 J:1.61 K:-66.29

07:06:18.182 : -9.0000 Delta Radius: 134.1331

07:06:18.186 : X-Tower Y-Tower Diag Rod: 276.5052

07:06:18.186 : Adjusting Delta Radius (134.13 -> 134.13)

07:06:18.190 : Adjusting Diag Rod Length (276.51 -> 276.51)

07:06:45.898 : Z-Tower Endstop Offsets

07:06:45.902 : -9.0125 -8.9875 Tower Position Adjust

07:06:45.906 : -10.4000 -10.3875 I:-3.20 J:1.61 K:-66.32

07:06:45.906 : -9.0125 Delta Radius: 134.1334

07:06:45.910 : X-Tower Y-Tower Diag Rod: 276.5052

07:06:45.910 : Adjusting Delta Radius (134.13 -> 134.13)

07:06:45.914 : Adjusting Diag Rod Length (276.51 -> 276.51)

Not sure what to do now.

Kirk

04:03:31.559 : TowerC Radius error - adjusting

04:03:31.563 : Adjusting Delta Radius (134.04 -> 134.04)

04:03:31.563 : Adjusting Diag Rod Length (276.51 -> 276.51)

04:03:58.525 : Z-Tower Endstop Offsets

04:03:58.529 : -7.8000 -7.6000 Tower Position Adjust

04:03:58.533 : -8.5625 -8.5500 I:-3.20 J:1.61 K:-53.82

04:03:58.533 : -7.6125 Delta Radius: 134.0357

04:03:58.537 : X-Tower Y-Tower Diag Rod: 276.5052

04:03:58.537 : Adjusting Delta Radius (134.04 -> 134.04)

04:03:58.541 : Adjusting Diag Rod Length (276.51 -> 276.51)

04:04:24.315 : Z-Tower Endstop Offsets

04:04:24.320 : -7.7250 -7.6375 Tower Position Adjust

04:04:24.324 : -8.5500 -8.6000 I:-3.20 J:1.61 K:-53.85

04:04:24.328 : -7.6500 Delta Radius: 134.0360

04:04:24.719 : X-Tower Y-Tower Diag Rod: 276.5052

04:04:24.720 : Adjusting Delta Radius (134.04 -> 134.04)

04:04:24.720 : Adjusting Diag Rod Length (276.51 -> 276.51)

07:06:18.174 : Z-Tower Endstop Offsets

07:06:18.178 : -9.0500 -8.9875 Tower Position Adjust

07:06:18.182 : -10.4000 -10.3750 I:-3.20 J:1.61 K:-66.29

07:06:18.182 : -9.0000 Delta Radius: 134.1331

07:06:18.186 : X-Tower Y-Tower Diag Rod: 276.5052

07:06:18.186 : Adjusting Delta Radius (134.13 -> 134.13)

07:06:18.190 : Adjusting Diag Rod Length (276.51 -> 276.51)

07:06:45.898 : Z-Tower Endstop Offsets

07:06:45.902 : -9.0125 -8.9875 Tower Position Adjust

07:06:45.906 : -10.4000 -10.3875 I:-3.20 J:1.61 K:-66.32

07:06:45.906 : -9.0125 Delta Radius: 134.1334

07:06:45.910 : X-Tower Y-Tower Diag Rod: 276.5052

07:06:45.910 : Adjusting Delta Radius (134.13 -> 134.13)

07:06:45.914 : Adjusting Diag Rod Length (276.51 -> 276.51)

Not sure what to do now.

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

For some reason the website has yet to update to the PDF to the new version, I'll get that sorted tonight.

That being said, the command to calibrate should be

The printers do come pre calibrated, but if you do see some problems with printing then running the calibration again will help.

Thanks!

Matt

Edit to add: the connections to the RAMPS board for the LCD might be a little loose from shipping if the encoder doesn't work, you can just push them back in lightly to reseat them.

That being said, the command to calibrate should be

- Code:

G30 A R125 D273

The printers do come pre calibrated, but if you do see some problems with printing then running the calibration again will help.

Thanks!

Matt

Edit to add: the connections to the RAMPS board for the LCD might be a little loose from shipping if the encoder doesn't work, you can just push them back in lightly to reseat them.

OrangeFurball- Admin

- Posts : 15

Join date : 2016-09-17

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

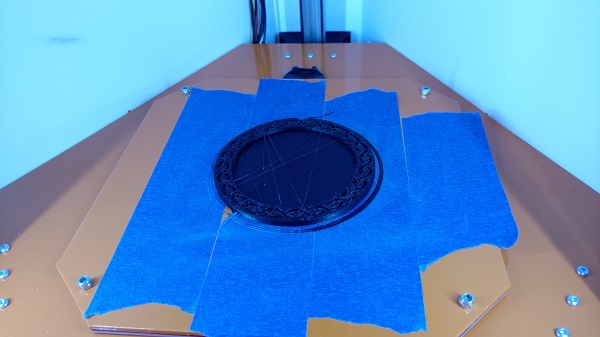

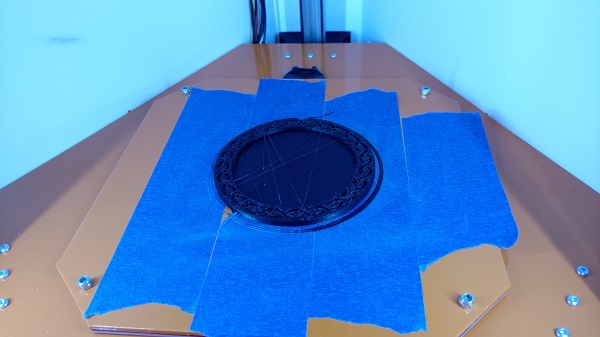

Finally found time to get back to it. Gave up on calibration, configured slic3r and repetier-host, switched to the extruder head, sliced one of my favorite test prints with what should be conservative settings (40mm/s perimeters, 0.2mm layers, autospeed 8mm^3/sec with 100mm/s max, loaded up the included black filament, and let it rip.

The left front tower Z is a bit too low, the head tore up the blue tape and mixed chunks into that corner. Otherwise everything is working as of layer 8/20. Need to read up on how to tweak delta Z clearance, all my experience is with a Printrbot.

More to follow...

Kirk

The left front tower Z is a bit too low, the head tore up the blue tape and mixed chunks into that corner. Otherwise everything is working as of layer 8/20. Need to read up on how to tweak delta Z clearance, all my experience is with a Printrbot.

More to follow...

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

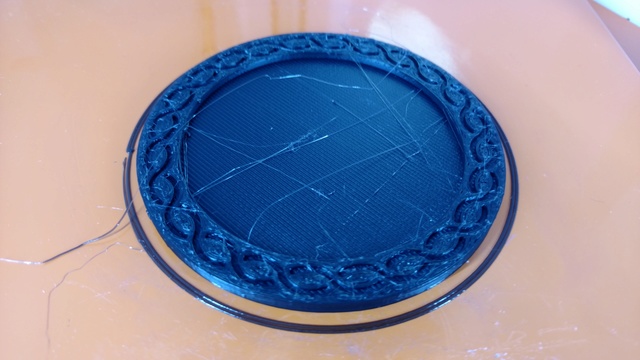

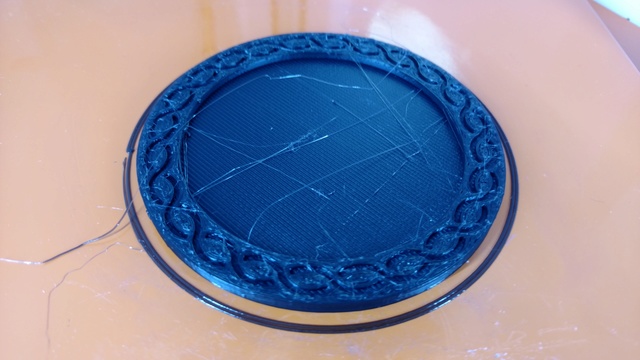

Finished! A bit of stringing (the retraction was set to 0.5mm for my metal Ubis, changed to 2mm), and I still need to figure out the best way to fix the Z clearance problem with the one tower. It's probably not as simple as adjusting that home switch, is it?

Kirk

Edit: Now I remember why I hate blue tape; destroyed the print taking it off.

Kirk

Edit: Now I remember why I hate blue tape; destroyed the print taking it off.

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Is the bed set for PWM control? That relay's clicking pretty fast for bang-bang?

Looks like I can adjust the X end stop position slightly to fix the low edge (M666 Xxxx), will try to do that with the paper thickness trick.

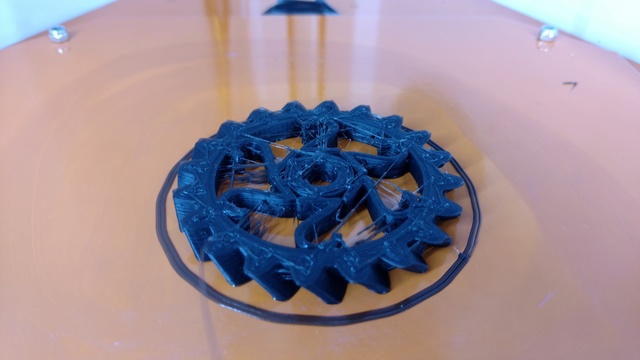

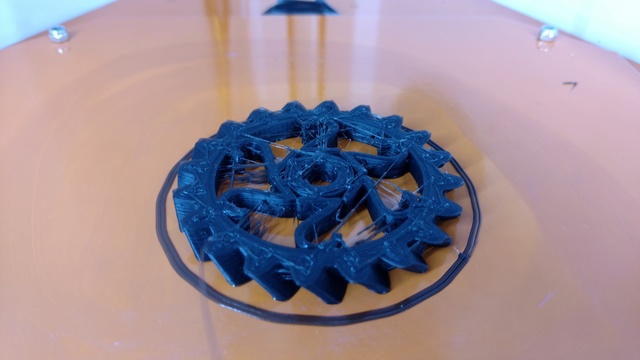

Trying print #2 with the temp bumped up, blue tape removed (gluestick on bed), and retract increased to 2mm. Still some stringing but better, need more retract. Came off the bed intact with a bit of persuasion.

For those who care it's a helical gear made with gearotic. The "2" spokes are appropriate..

Kirk

Looks like I can adjust the X end stop position slightly to fix the low edge (M666 Xxxx), will try to do that with the paper thickness trick.

Trying print #2 with the temp bumped up, blue tape removed (gluestick on bed), and retract increased to 2mm. Still some stringing but better, need more retract. Came off the bed intact with a bit of persuasion.

For those who care it's a helical gear made with gearotic. The "2" spokes are appropriate..

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Yep! You can just adjust the endstop screws or even tighten the low corner of the bed if the clearance issue isn't too high. The bed is on foam to add space for the thermistor but the foam can be squished a bit more if it needs to.

Beds are set to bang bang, I'll look into some firmware changes to try and stop the clicking.

As for retraction settings I use 4.5mm at 40mm/s, it might not be the best setting (you can probably go lower) but I have yet to have a reason to change to anything else on all of my printers.

Beds are set to bang bang, I'll look into some firmware changes to try and stop the clicking.

As for retraction settings I use 4.5mm at 40mm/s, it might not be the best setting (you can probably go lower) but I have yet to have a reason to change to anything else on all of my printers.

OrangeFurball- Admin

- Posts : 15

Join date : 2016-09-17

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

I thought changing the screw might cause calibration issues. Looks like M666 Xxxx might be an option, and maybe even M206Xxxx if that affects the X tower and not the pseudo X axis.

I only need a few tenths of a mm, twisting the screw is the easiest

The overnight "M30 A" calibration run said the diagonal rods were 276.5052mm (pretty quickly, actually), but my handy Helix stainless ruler says they're pretty darn close to 273. Could be why it never finished. Ran a few iterations with the variant you said to use, but killed it after about 10 iterations; time to just try it.

I labeled the towers X,Y,Z clockwise starting in the left front, matching what I could find online. Didn't want to start pulling wires loose to trace them, so the low tower would be the X. During the overnight calibration it ran the Z to the endstop and kept going (missing steps, of course) after that several times. Is that normal, or perhaps something to do with the arm length thing?

These delta are a bit strange compared to simple cartesian bots Bunch of new things to learn...

Bunch of new things to learn...

Kirk

I'll bump the retraction up to 4mm; will be putting in a couple fence posts and other outdoor chores today so the TBD gets a rest until later in the day.

Kirk

I only need a few tenths of a mm, twisting the screw is the easiest

The overnight "M30 A" calibration run said the diagonal rods were 276.5052mm (pretty quickly, actually), but my handy Helix stainless ruler says they're pretty darn close to 273. Could be why it never finished. Ran a few iterations with the variant you said to use, but killed it after about 10 iterations; time to just try it.

I labeled the towers X,Y,Z clockwise starting in the left front, matching what I could find online. Didn't want to start pulling wires loose to trace them, so the low tower would be the X. During the overnight calibration it ran the Z to the endstop and kept going (missing steps, of course) after that several times. Is that normal, or perhaps something to do with the arm length thing?

These delta are a bit strange compared to simple cartesian bots

Kirk

I'll bump the retraction up to 4mm; will be putting in a couple fence posts and other outdoor chores today so the TBD gets a rest until later in the day.

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Adjusted the X tower endstop so that corner didn't drag, upped the retraction to 4mm, tweaked the slic3r settings a little and much better results. Stringing still not gone (increased retraction setting to 4.5mm for next time), and the first layer is a bit high (about .2 mm at Z0) so it underextrudes only that layer. The strings brushed off with very little work (unlike the helical gear which I'm still xacto-knifing off strings), and the resulting coaster is the best I've gotten in a while. The TBD is tying or beating my KSCP (plywood printrbot) almost out of the box, and that's before hammering at it with the test suite.

I'm using essentially the same settings I use on my Printrbot for speed and layer thickness, that bot is limited by the about 10mm^3/sec the all metal Ubis will extrude. I'm expecting lot better from the E3D with it's higher power heater and plan to test that "real soon now".

I noticed the motors are barely above room temperature, and thus aren't running anywhere near their total potential. Steppers can run quite hot (the standard test is you can hold your finger on them for 5 to 10 seconds) which will not hurt the motors - they're made with high temperature motor winding insulation (the insulation has a "class" which defines it's temperature range, haven't tried to look up these Keling Tech steppers yet). While it's not necessary to run them flat out keeping the current excessively low will limit their acceleration and speed potential - the story that cranking the current way down to increase the motor life is a myth (geckodrive.com has a lot of good info on steppers and drivers). Now to figure out how to get these hooves in there and adjust those tiny motor pots up a bit.

Our local high school has a half dozen plywood and linear rod deltas built by a tech at the local university (who, for some strange reason, adds a Beaglebone Black used like an Octoprint Raspberry Pi, without taking any advantage of it's CNC driving capabilities (like 200K+ steps/sec using LinuxCNC and the boards Programmable Realtime Units (PRUs). They also have a Melzi controller), and the teacher runs them at 500mm/sec. While I don't believe (and they don't look like) they're really hitting that speed, Marlin is steprate limited to a somewhat under 20K steps/sec), they're still quicker than the 100mm/sec I've been printing at. Something else to combine with the motor current investigations.

Matt, you should think about including one of those cheap Torx allen keys, the smallest Torx driver I have is T10, and they're smaller than that. What size are they?

I should warn you, gentle readers, that I'm a retired engineer and hardcore tinkerer and like to poke, prod, and generally harass my printers to find out what their limits are. Speed vs print quality is a trade off and personal decision, and while I tend towards the speed end of the scale you may not. YMMV...

Kirk

I'm using essentially the same settings I use on my Printrbot for speed and layer thickness, that bot is limited by the about 10mm^3/sec the all metal Ubis will extrude. I'm expecting lot better from the E3D with it's higher power heater and plan to test that "real soon now".

I noticed the motors are barely above room temperature, and thus aren't running anywhere near their total potential. Steppers can run quite hot (the standard test is you can hold your finger on them for 5 to 10 seconds) which will not hurt the motors - they're made with high temperature motor winding insulation (the insulation has a "class" which defines it's temperature range, haven't tried to look up these Keling Tech steppers yet). While it's not necessary to run them flat out keeping the current excessively low will limit their acceleration and speed potential - the story that cranking the current way down to increase the motor life is a myth (geckodrive.com has a lot of good info on steppers and drivers). Now to figure out how to get these hooves in there and adjust those tiny motor pots up a bit.

Our local high school has a half dozen plywood and linear rod deltas built by a tech at the local university (who, for some strange reason, adds a Beaglebone Black used like an Octoprint Raspberry Pi, without taking any advantage of it's CNC driving capabilities (like 200K+ steps/sec using LinuxCNC and the boards Programmable Realtime Units (PRUs). They also have a Melzi controller), and the teacher runs them at 500mm/sec. While I don't believe (and they don't look like) they're really hitting that speed, Marlin is steprate limited to a somewhat under 20K steps/sec), they're still quicker than the 100mm/sec I've been printing at. Something else to combine with the motor current investigations.

Matt, you should think about including one of those cheap Torx allen keys, the smallest Torx driver I have is T10, and they're smaller than that. What size are they?

I should warn you, gentle readers, that I'm a retired engineer and hardcore tinkerer and like to poke, prod, and generally harass my printers to find out what their limits are. Speed vs print quality is a trade off and personal decision, and while I tend towards the speed end of the scale you may not. YMMV...

Kirk

Last edited by Mooselake on Fri Nov 04, 2016 1:06 pm; edited 1 time in total (Reason for editing : Add photp)

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Well, needed to eat some humble pie, guess hooves aren't good tools for sketching math equations. Revised the test program to resolve a missing 1/x, edit of yesterday's post, below.

Here's some gcode to test for the printer's maximum extrusion rate in both cubic mm/sec (mm^3/sec) and mm/sec with 1.73mm diameter filament. Might be a little rough but it works in Mooseland. Edit the source to change the temperature, currently set at 220 degrees. Hopefully the math is correct. This time, had it wrong yesterday. One mm of 1.75 filament is (1.75/2)^2*pi, or about 2.4 cubic mm. If you invert that (the step the moose missed) then you get 0.42 mm of extrusion per mm^3 of plastic. Multiply that by the cubic millimeters per second you want and you get, for example,

6 mm^3 times 0.42 mm

sec mm^3

Going back to those summer of '69 college chemistry classes where Doc Berry taught all that cancelling out, you get 6*0.42, or about 2.5mm/sec. The Moose had 14.10 because of that missed inversion. Bad Moose.

The All Metal Ubis (superceeded by the Ubis 13 and then the Ubis 13S) on my Printrbot was capable of reliably extruding 8 mm^3. The Mighty E3D is skipping just a bit at 20, and noticeably at 24. Using 80% for a safety factor you get 16cu mm a sec safe printing speed; twice that of the AMU! Using 0.3mm layers and 0.5mm extrusion width (let's ignore the whole curved edge problem) it takes 0.15 cu mm per mm of extrusion, or 6.7 mm per mm^3. 16 mm^3 per second gives you 107mm/sec print speed. Better than the less than 50 I got with the error.

The gcode is inline below, so copy and paste it into a file to test. It'll pause between rate steps, and display the volumetric rate and speed on the LCD (Repetier-Host overwrites it fairly quick with the estimated time to completion). The forum won't attach it directly, need to investigate how to do so with the file storage account it gave me.

Kirk

Here's some gcode to test for the printer's maximum extrusion rate in both cubic mm/sec (mm^3/sec) and mm/sec with 1.73mm diameter filament. Might be a little rough but it works in Mooseland. Edit the source to change the temperature, currently set at 220 degrees. Hopefully the math is correct. This time, had it wrong yesterday. One mm of 1.75 filament is (1.75/2)^2*pi, or about 2.4 cubic mm. If you invert that (the step the moose missed) then you get 0.42 mm of extrusion per mm^3 of plastic. Multiply that by the cubic millimeters per second you want and you get, for example,

6 mm^3 times 0.42 mm

sec mm^3

Going back to those summer of '69 college chemistry classes where Doc Berry taught all that cancelling out, you get 6*0.42, or about 2.5mm/sec. The Moose had 14.10 because of that missed inversion. Bad Moose.

The All Metal Ubis (superceeded by the Ubis 13 and then the Ubis 13S) on my Printrbot was capable of reliably extruding 8 mm^3. The Mighty E3D is skipping just a bit at 20, and noticeably at 24. Using 80% for a safety factor you get 16cu mm a sec safe printing speed; twice that of the AMU! Using 0.3mm layers and 0.5mm extrusion width (let's ignore the whole curved edge problem) it takes 0.15 cu mm per mm of extrusion, or 6.7 mm per mm^3. 16 mm^3 per second gives you 107mm/sec print speed. Better than the less than 50 I got with the error.

The gcode is inline below, so copy and paste it into a file to test. It'll pause between rate steps, and display the volumetric rate and speed on the LCD (Repetier-Host overwrites it fairly quick with the estimated time to completion). The forum won't attach it directly, need to investigate how to do so with the file storage account it gave me.

Kirk

- Code:

M104 S220 ; number after S is extruder temperature

;

G90 ; absolute postitioning

G28 ; home

M106 S0 ; turn off fan, if you have one

M109 ; wait for extruder to heat up

G92 E0

M117 14mm^3/sec 6.02mm/sec

G1 E21.50 F361.20 ; Extrude

G4 P2000 ; wait a bit

G92 E0

M117 16mm^3/sec 6.88mm/sec

G1 E21.50 F412.80 ; Extrude

G4 P2000 ; wait a bit

G92 E0

M117 18mm^3/sec 7.74mm/sec

G1 E21.50 F464.40 ; Extrude

G4 P2000 ; wait a bit

G92 E0

M117 20mm^3/sec 8.60mm/sec

G1 E21.50 F516.00 ; Extrude

G4 P2000 ; wait a bit

G92 E0

M117 22mm^3/sec 9.46mm/sec

G1 E21.50 F567.60 ; Extrude

G4 P2000 ; wait a bit

G92 E0

M117 24mm^3/sec 10.32mm/sec

G1 E21.50 F619.20 ; Extrude

G4 P2000 ; wait a bit

G28 ; home printer

M104 S0 ; turn off extruder heater

Last edited by Mooselake on Mon Nov 07, 2016 3:32 pm; edited 2 times in total (Reason for editing : Moose Math Failure)

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Printed off another Celtic Coaster (well, they make decent 3Dp examples to hand out) with slic3r autospeed set at 16 mm^3/sec and 120mm/sec max. Still need to work on the stringing, but it looks really good.

Still want to up the current on those Keling KL17H248-15-4A 5.5 Kg-cm steppers. They're listed as class B motor insulation (130C/266F) max winding temps. You don't want to run them anyway near that hot, but now they're barely above room temp. It's not unreasonable to increase the current and see if they'll push out more plastic without getting much warmer while staying well out of warranty terminating (or plastic softening at the gear) temps. Time to break out the IR thermometer and ceramic screwdrivers on the next rainy day, after perusing the docs over at geckodrive.com a bit.

Gotta say Matt's made an impressive printer, plus all the rework he's done to fix issues before youse guys get yours.

Kirk

Still want to up the current on those Keling KL17H248-15-4A 5.5 Kg-cm steppers. They're listed as class B motor insulation (130C/266F) max winding temps. You don't want to run them anyway near that hot, but now they're barely above room temp. It's not unreasonable to increase the current and see if they'll push out more plastic without getting much warmer while staying well out of warranty terminating (or plastic softening at the gear) temps. Time to break out the IR thermometer and ceramic screwdrivers on the next rainy day, after perusing the docs over at geckodrive.com a bit.

Gotta say Matt's made an impressive printer, plus all the rework he's done to fix issues before youse guys get yours.

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Just a bump. The weather's been nice, way warmer than usual, and the outside chore list never ends. Imagine a moose wearing florescent safety yellow chainsaw chaps wielding an orange Husquvarna 61 chainsaw. Still a couple more full cords to go, then order another 11C logging truck load, to get ready to feed the hungry smoke belching outdoor wood boiler. Hired a couple carpenters to (finally) put the shed around it, the material arrives tomorrow. With luck that'll put it on at least a little bit of a diet, Pus no more standing outside in a blizzard feeding it (although it's still a 60'/20m hike from the house to the boiler).

Anybody else get theirs yet?

Kirk

Anybody else get theirs yet?

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Excellent information here as always, Kirk.

I'm glad that someone else is running the printer through its paces, there are a few hiccups here and there that I am working out as things progress.

The Deltas use three different Torx sizes'; T25, T10, and T8 for the screws that bit the plastic. I love Torx screws but I should have thought the choice through. Not many people have a large variety of Torx bits lying around. The new models will most certainly be hex or Phillips head screws.

That is [unfortunately] normal. I happens every once in a while during calibration, but with the past few that I have built and boxed up I haven't had it occur. I've tried squashing that bug along with countless others in the firmware but nothing has been fixed yet (in fact, in a few of the "fixed" versions even more calibration stuff was broken!)

I'll spend more time on that once I have more printers out. I had some more shipping issues (of course) but am ready to start shoving printers out the door after Thanksgiving.

I did post the current STLs and firmware to Thingiverse for anyone who wants to tinker http://www.thingiverse.com/thing:1913346

Thanks,

Matt

I'm glad that someone else is running the printer through its paces, there are a few hiccups here and there that I am working out as things progress.

The Deltas use three different Torx sizes'; T25, T10, and T8 for the screws that bit the plastic. I love Torx screws but I should have thought the choice through. Not many people have a large variety of Torx bits lying around. The new models will most certainly be hex or Phillips head screws.

During the overnight calibration it ran the Z to the endstop and kept going (missing steps, of course) after that several times. Is that normal, or perhaps something to do with the arm length thing?

That is [unfortunately] normal. I happens every once in a while during calibration, but with the past few that I have built and boxed up I haven't had it occur. I've tried squashing that bug along with countless others in the firmware but nothing has been fixed yet (in fact, in a few of the "fixed" versions even more calibration stuff was broken!)

I'll spend more time on that once I have more printers out. I had some more shipping issues (of course) but am ready to start shoving printers out the door after Thanksgiving.

I did post the current STLs and firmware to Thingiverse for anyone who wants to tinker http://www.thingiverse.com/thing:1913346

Thanks,

Matt

OrangeFurball- Admin

- Posts : 15

Join date : 2016-09-17

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

I haven't done anything with the TBD since my last post; we've had a run of good weather and the overly long outside project list needed some pruning from too much procrastination. The outdoor boiler now has a 14'6" x 16' shed around it, intended to be attached to the old woodshed. The woodshed has sunk into the ground close to a foot in spots, and while there might have been sill plates under it all that remained on the wall I'm working on is a few rusted out nails pointing into the dirt. Jack, hammer, cut off rusty nails, bigger hammer to beat in the new sill (rough 2x4 over a treated 2x6), plus a bit of running for the door when it starts creaking. Followed by prying, more persuading, adult language, replacing and reinforcing rotten bits...

Hope to get back to the TBD in a few days, need to finish up the manually adjustable K40 laser table so I can install the new Coherent3D smoothieware based controller. Keep this up and I'll be as busy as Matt

Time for somebody else to start posting about their new TBDs!

Kirk

Hope to get back to the TBD in a few days, need to finish up the manually adjustable K40 laser table so I can install the new Coherent3D smoothieware based controller. Keep this up and I'll be as busy as Matt

Time for somebody else to start posting about their new TBDs!

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

After a month of idleness, er, furiously trying to get the outside work done before the arctic blasts, some free time presented itself. Time to fire up the TBD!

When last activated I was trying to print a copy of the Michigan Tech Husky Statue and having trouble with removing the support (slic3r issue, not TBD). Prusa has recently released a modified slic3r with improved support (and lots of other things), so this was a good chance to try it out.

Unfortunately I found the filament broken off at the spool, and jammed in the bowden tube, requiring that I remove the PTFE tube. I found that both ends had mushroomed and wouldn't fit through the tube so I couldn't pull it out; clipping the bulges sorted it out. Additionally the setscrew on the extruder drive gear had worked loose (like Jeremy's). Realignment and removing the screw and adding some fake HF blue Loctite (the good stuff was two floors down in the Moosecave) before tightening fixed that (perhaps the Furball needs a bottle of the real thing).

So far the modified slic3r isn't working out too well, but that's likely a configuration issue. I use volumetric autospeed (15mm^3/sec, 120 max, 40mm/sec perimeters) and the first few layers are both underextruded and incredibly slow. Alas my time window has vanished (need to do a game standby for work), so it won't be sorted out today. Later...

Kirk

When last activated I was trying to print a copy of the Michigan Tech Husky Statue and having trouble with removing the support (slic3r issue, not TBD). Prusa has recently released a modified slic3r with improved support (and lots of other things), so this was a good chance to try it out.

Unfortunately I found the filament broken off at the spool, and jammed in the bowden tube, requiring that I remove the PTFE tube. I found that both ends had mushroomed and wouldn't fit through the tube so I couldn't pull it out; clipping the bulges sorted it out. Additionally the setscrew on the extruder drive gear had worked loose (like Jeremy's). Realignment and removing the screw and adding some fake HF blue Loctite (the good stuff was two floors down in the Moosecave) before tightening fixed that (perhaps the Furball needs a bottle of the real thing).

So far the modified slic3r isn't working out too well, but that's likely a configuration issue. I use volumetric autospeed (15mm^3/sec, 120 max, 40mm/sec perimeters) and the first few layers are both underextruded and incredibly slow. Alas my time window has vanished (need to do a game standby for work), so it won't be sorted out today. Later...

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Re: Thingybotting in Mooselake

Re: Thingybotting in Mooselake

Bump. Just returned from a trip to the right (geographically, the opposite of left, not a political comment) coast for one of the three 3 daughters rare same place/time events. Now that there's a couple feet of snow on the ground maybe there will be time to get something done with the TBD. Need to print some electronic project cases for the stack of pending Arduino Nano projects now that the boards have arrived on the slow boat.

Wanted to take the MTU Husky statue with us (the oldest is a Tech grad) but that didn't work out. Shouldn't being semi-retired make more free time?

Kirk

Wanted to take the MTU Husky statue with us (the oldest is a Tech grad) but that didn't work out. Shouldn't being semi-retired make more free time?

Kirk

Mooselake- Admin

- Posts : 71

Join date : 2016-09-21

Age : 104

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|